When it comes to hydraulics – for certain large machines and equipment – there are branches of a fluid power circuit that need to operate at a lower pressure. A pressure-reducing valve assists with that important job, which can prevent machine damage and a hefty bill.

A pressure-reducing valve maintains lower pressures in branches of hydraulic systems. The system relief valve or other pressure-setting device determines upstream main system pressure. A pressure-reducing valve is normally an open, 2-way valve that allows system pressure fluid to flow through it until a set pressure is reached downstream. It then shifts to throttle flow into the branch.

The forces exerted by pressure downstream actuates a pressure-reducing valve. A pressure drop across the valve’s spring-based main spool is created by the forces establishing the working pressure needed. The desired pressure setting is maintained by the position of it’s main spool adjusting continuously.

Basically, the pressure-reducing valve controls the downstream pressure or outlet. Here is a more in-depth description of 3 pressure-reducing valve’s functions in hydraulic settings:

1. Self-Relieving Type Air Line Regulator

For a pneumatic circuit, the air line regulators reduce pressure. Energy can be saved by reducing pressure whenever possible, because air in the supply line to a machine is at maximum pressure. For example, about half of the input energy would be lost without a properly adjusted regulator with a machine requirement of 60 psi and a compressor setting of 120 psi. The air-driven machine consumes more compressor horsepower than what is necessary when it works at the higher pressure.

For the retraction strokes of air cylinders, air line regulators are also very useful. A cylinder’s retraction stroke consumes less compressor horsepower when it saves air from reduced pressure.

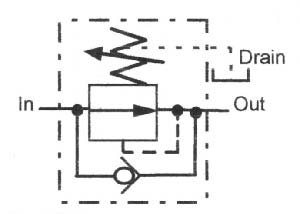

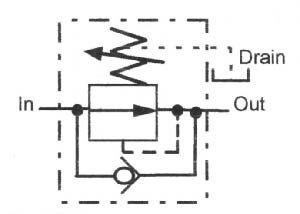

2. Pressure-Reducing Valve with Bypass Check Valve

A standard reducing valve is normally open. When downstream pressure goes higher than its setting, the valve closes, which blocks the flow. Pressure downstream may try to increase. When there’s resistance from an opposing cylinder, for instance, a reducing valve also blocks the reverse flow. Something could burst or get mechanically damaged if the accelerated pressure in the downstream line would continue.

In multiple actuator circuits, it is often impossible to size all actuators to operate at maximum system pressure. Here’s a good example of this: a cylinder needs a certain number of pounds of force, but, even at maximum pressure, a standard bore does not produce enough. In this case, the designer must go to the next largest standard bore. However, the next largest bore produces too much force. Doing this can cause machine or part damage. Instead, install a pressure-reducing valve in the branch circuit with the over-sized cylinder to lower that branch’s pressure to generate the required cylinder force.

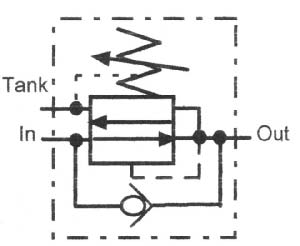

3. Pressure-Reducing-Relieving Valve with Bypass Check Valve

Maximum outlet pressure is set by a reducing-relieving valve. When the outlet pressure tries to go higher (due to high temperatures or outside sources), it relieves fluid to the tank. A reducing-relieving valve has a full-flow line to tank with an integral relief valve. Trapped fluid relieves to the tank when pressure in the downstream circuit rises 3-5 percent above reduced pressure. Adjusting the reduced pressure automatically sets the maximum relief pressure.

Note: There is always a drain line open to the tank to control oil flow with hydraulic pressure-reducing valves. When the pressure-reducing valve’s outlet is lower than its inlet, drain oil flows. This creates a small amount of heat in the system. Blocking the drain line lets the outlet pressure rise to system pressure by forcing the valve wide open.

Dec 16, 2016 - 03:55 PM

I appreciate the information on how pressure reducing valve work with hydraulics. I would imagine that a pressure releasing valve can be a life saver when it comes to hydraulic hoses and keeping them working for a long time. My brother has been having issues with his hydraulic hoses, I will share this information with him about the pressure releasing valves.